Low battery

Battery level is below 20%. Connect charger soon.

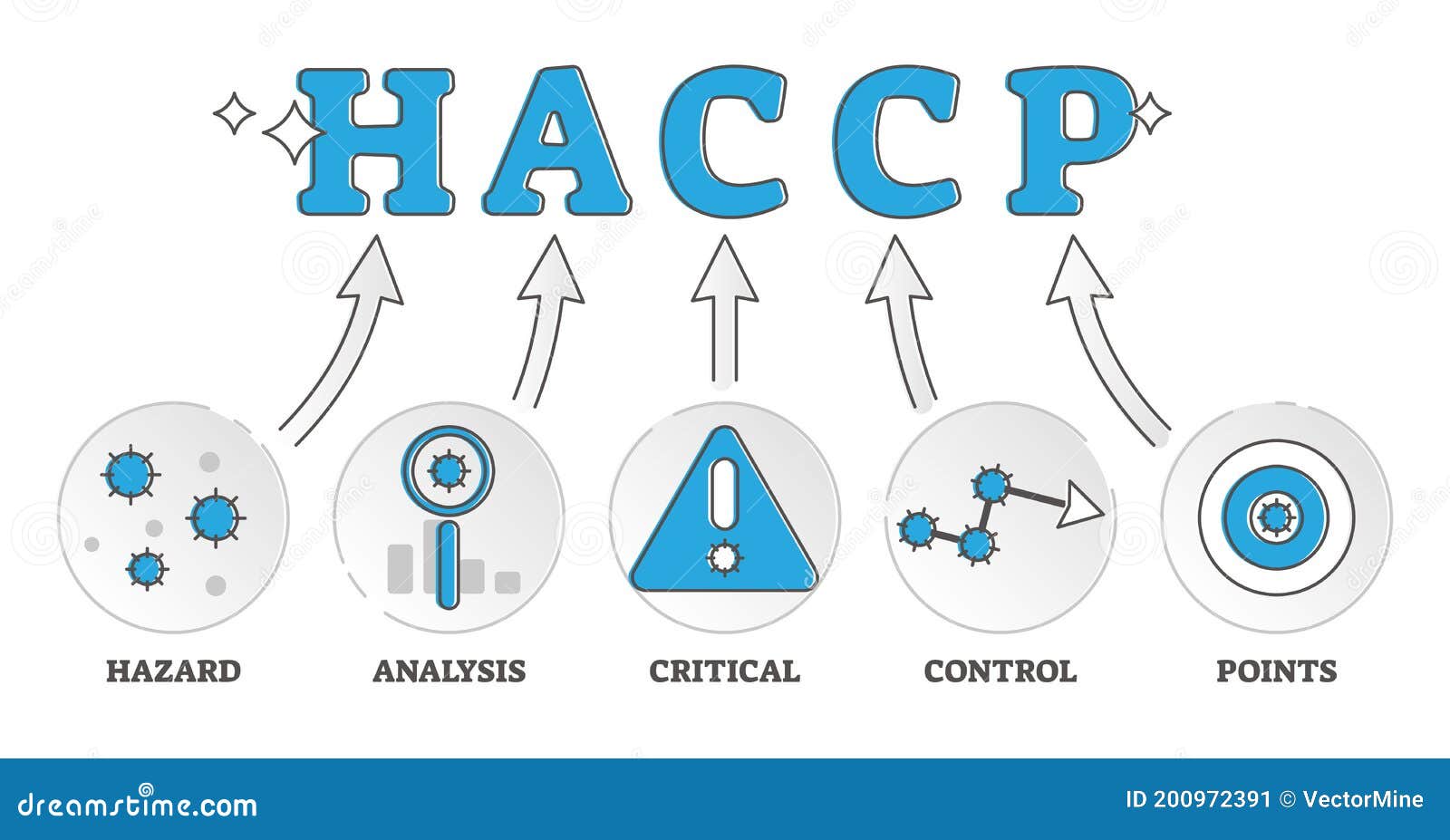

Haccp (hazard analysis critical control point) is defined as a management system in which food safety is addressed through the analysis and control of biological, chemical, and physical hazards from raw material production, procurement and handling, to manufacturing, distribution and consumption of the finished product. Haccp is an internationally recognized method of identifying and managing food safety related risk and, when central to an active food safety program, can provide your customers, the public, and regulatory agencies assurance that a food safety program is well managed. It involves identifying, evaluating, and controlling hazards significant for food safety. ‘haccp’ stands for hazard analysis critical control points, and is a food safety and risk assessment plan that was initially developed in the 1960s by nasa to solve two critical problems facing nasas crewed space missions: · haccp is based on seven principles: Bacteria, viruses) or toxins. Crumbs and disease-producing microorganisms (e. g. It is based on prevention – identifying possible hazards before they occur and defining control measures to maximize food safety at every step of the food production and handling processes. · haccp — which stands for hazard analysis and critical control points — is a systematic approach to identifying, evaluating, and controlling food safety hazards. It’s built on seven fundamental principles, each of which builds upon the information that was obtained from the previous principal. Its definition, significance in food safety, detailed process, and core principles. Haccp is a management tool for ensuring food safety. · explore haccps essence: Conducting a hazard analysis, determining critical control points (ccps), establishing critical limits, monitoring ccps, taking corrective actions, verifying the system, and documenting procedures and records. Haccp is a management system in which food safety is addressed through the analysis and control of biological, chemical, and physical hazards from raw material production, procurement and. Hazard analysis and critical control points, or haccp (/ ˈhæsʌp / [1]), is a systematic preventive approach to food safety from biological, chemical, and physical hazards in production processes that can cause the finished product to be unsafe and designs measures to reduce these risks to a safe level. Dive into the system ensuring culinary safety. · haccp (hazard analysis and critical control points) is a systematic preventive approach to food safety.